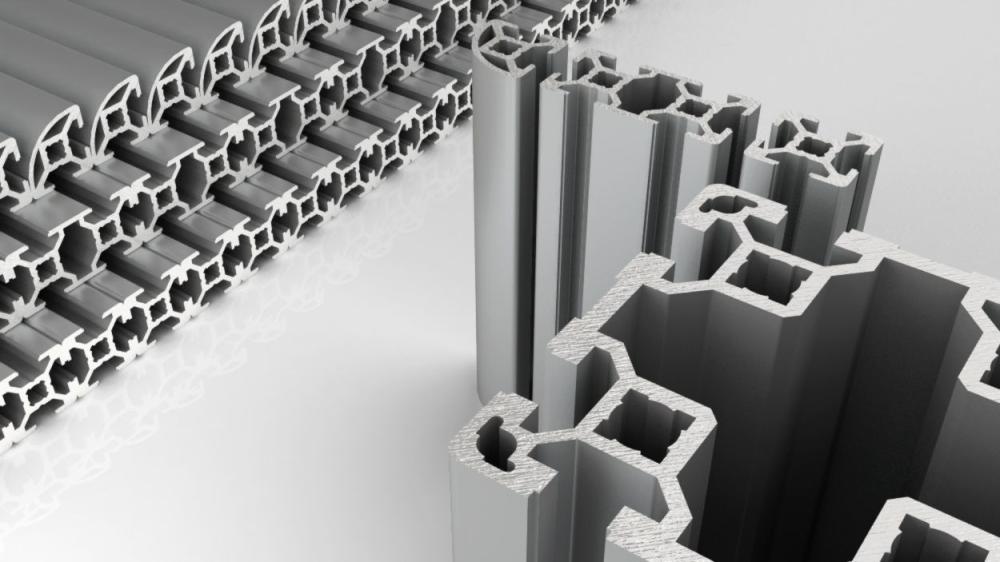

Extrusion profile: strong, light and modular for every application

An extrusion profile is an aluminium profile formed by forcing molten aluminium through a die under high pressure.

This technology enables the production of structural profiles with precise shapes, tight tolerances, and optimal strength-to-weight ratios.

At Bendur, we supply extrusion profiles specifically designed for modular construction, bodywork, and transport systems. From machine frames and toilet trailers to logistics installations: our profiles are designed for rapid construction, easy modification, and long-lasting durability.

What is an extrusion profile?

The extrusion process produces aluminum profiles that:

-

Lightweight, yet strong enough for load-bearing applications

-

Corrosion-resistant thanks to an anodized finish

-

Consistent dimensions for a perfect fit

-

Easy to machine with standard tools

Extrusion profiles for building machine frames or creating guards are also called system profiles, construction profiles, or structural profiles. All are variations of the same principle.

Advantages of an extruded aluminum profile

An extruded aluminum profile is more than just a piece of metal.

The combination of smart design, lightweight material, and high dimensional stability makes these profiles the ideal building blocks for systems that must be fast, durable, and scalable. Whether it's a complete transport system, toilet trailer, or a single machine frame, the benefits are clear:

- Modular and flexible – easy to adapt or expand

- Sustainable – less waste, long service life

- Quick to assemble – fewer on-site hours, less downtime

- Interchangeable – compatible with Bendur accessories and components

- Widely applicable – conveyors, work tables, machine frames, and more

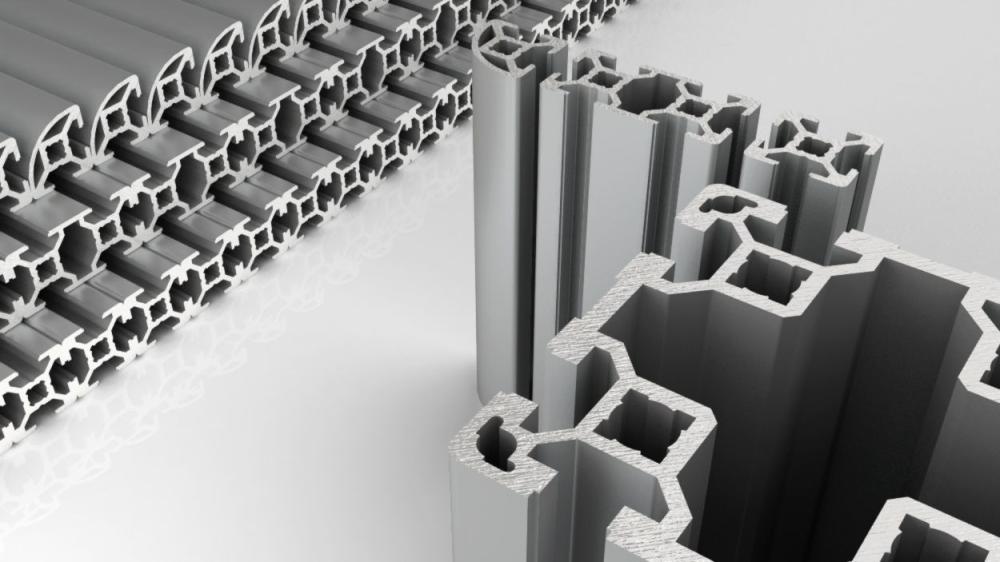

Bendur construction profiles: ISB and BSB

Bendur supplies extrusion profiles for mechanical engineering, shielding and construction in two variants:

- ISB profiles – Compatible with the ITEM Profile System

- BSB profiles – Compatible with the Bosch-Rexroth Profile System

Applications of Bendur extrusion profiles

Furthermore, our profiles are used in:

- Transport systems and logistics installations

- Machine frames and technical structures

- Work tables and production lines

- Trucks

- Toilet trucks and sales vans

- Trailer construction

- Cupboards and shelving

- Creative applications by technical builders and integrators

- Creative structures for both professionals and private individuals

Sustainable and scalable construction

With extrusion profiles, you build only what you need and can easily expand later. This makes it not only cost-efficient but also sustainable: no unnecessary material use and less waste.

Frequently Asked Questions

What is the difference between an extrusion profile and a standard aluminum profile?

There's really no difference between the products, only the wording. Both are extruded, but profiles you can't buy at the hardware store are considered extrusion profiles, while aluminum angle, U, and L profiles are considered standard profiles. That's why we call these hardware store profiles "trade profiles," and you could say that all other profiles, such as custom-made or prefabricated profiles, that use the same production methods, can be called extrusion profiles.

Can I use ISB and BSB in one construction?

This is not recommended. Although very similar, they are different systems, and therefore the individual components won't fit together. Therefore, the two systems are placed in separate categories in our webshop, each with its own color icon.

How quickly are Bendur profiles available?

Many sizes and variants are available directly from stock, and this is indicated with the item in our webshop. Custom extrusion profiles can also be produced quickly, but please allow 6 weeks for the production of a sample piece and another 4-6 weeks for the production of the extrusion profile.