ISB vs. BSB Profiles: What's the Difference and Which One Should You Choose for Your Project?

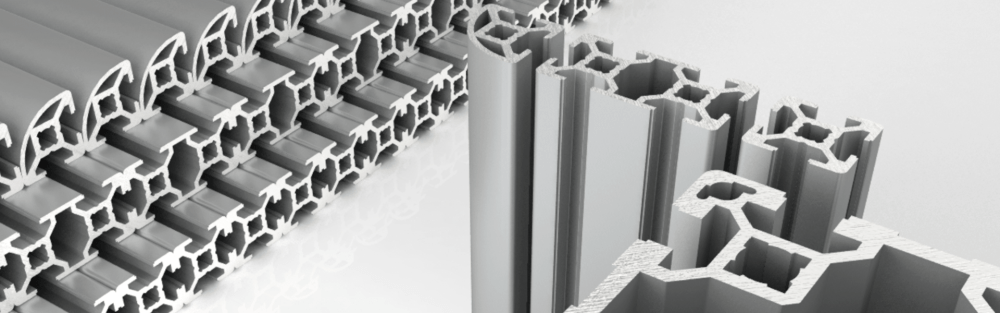

Aluminum profiles are indispensable in modern mechanical engineering, shielding, internal transport systems, shelving, and custom constructions. They are also called extrusion profiles, construction profiles, system profiles, or building profiles.

Aluminum profiles: one product, many names

The name varies by sector, but the basis is the same: a strong, lightweight, and modular profile. The combination of low weight, high strength, and ease of machining has made the aluminum profile the standard for countless technical applications.

Bendur supplies two main types of extrusion profiles

At Bendur, you'll find extrusion profiles in two systems:

ISB profiles – interchangeable with the ITEM Profile System

BSB profiles – interchangeable with the Bosch-Rexroth Profile System

Both are modular, durable, and suitable for use in a wide range of technical environments. At first glance, the ISB and BSB profiles appear very similar, including in shape and appearance. However, there are clear differences that are important in practice.

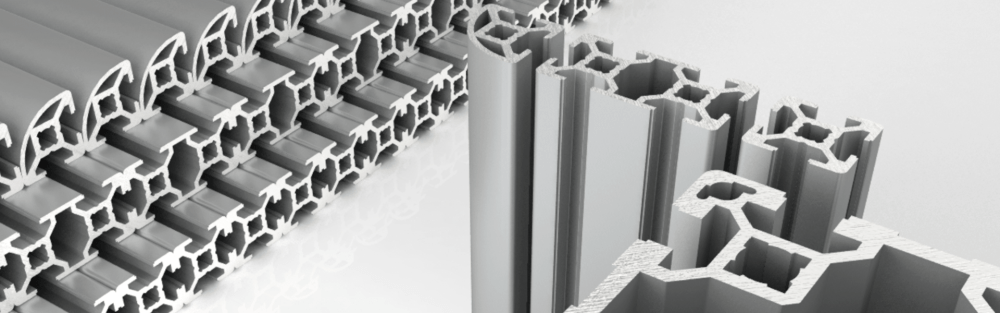

The slot types, in particular, differ when the profiles have the same dimensions. For example, a 40x40 BSB profile has a slot 10, while a 40x40 ISB profile can have a slot 5 or 8. This makes a difference in the compatible components and the way you mount accessories or fasteners.

The weight also differs: the ISB profile has a slightly higher mass and is therefore slightly heavier, while the BSB profile is lighter and is often chosen for more industrial constructions. In addition, the shape of the groove in ISB is rounder and the profile shape is more 'design-oriented', where the BSB groove looks tighter and has a more functional appearance.

The differences between ISB and BSB profiles

Small profiles (20x20, 30x30)

BSB profiles are lighter and more cost-effective, while ISB profiles are stiffer and stronger. BSB is often sufficient for lightweight constructions, but ISB is preferred for applications where accuracy or stiffness is important.

Medium-sized profiles (40x40L, 80x40L, 80x80L)

These profiles are the most commonly used. ISB generally scores better in torsional and bending stiffness, while BSB is lighter and sometimes more advantageous in the X-direction. The choice depends primarily on the application: increased stiffness (ISB) or reduced weight (BSB).

Heavy-duty profiles (120x40L, 120x80L, 160x40L, 160x80L)

With heavy-duty profiles, the differences between the X and Y directions are more pronounced. ISB is often stiffer in the Y direction, while BSB is stiffer in the X direction. With mirrored named profiles (such as 120x80L ↔ 80x120L) they are technically the same, with a small variation in weight and torsional stiffness.

Applications of ISB and BSB profiles

ISB profiles are widely used for:

- Display cases and presentation furniture

- Shelving and lightweight frames

- Constructions where aesthetics are important

BSB profiles are ideal for:

- Machine frames and industrial structures

- Transport and conveyor systems

- Heavy-duty applications requiring extra stability

Why choose aluminium profiles from Bendur?

- Modular – easy to assemble, modify, and expand

- Compatible – compatible with major system standards (ITEM & Bosch-Rexroth)

- Durable – long lifespan, reusable, and recyclable

- Fast delivery – many profiles available directly from stock

- Technical advice – we help you find the best solution for your application

What suits your project?

Are you unsure whether to choose an ISB or BSB profile? Then contact our team for advice. We're happy to help, whether you're working on a large construction project in mechanical engineering or logistics, or a small private project.