ConveyorBricks by Bendur

Modular conveyor components, from the Netherlands.

Bendur ConveyorBricks is our ode to system integrators.

Bendur was founded on a passion for technology, hardware, and engineering. With a wide, competitively priced range and a large inventory, we can deliver quickly throughout Europe. Bendur ConveyorBricks is the logical next step.

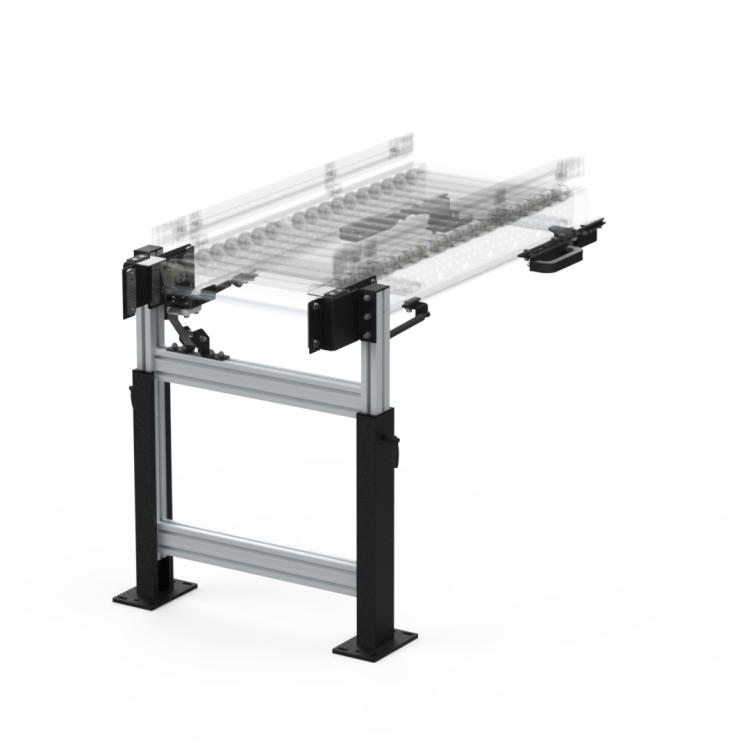

After years of designing, building, and testing, we're proud to launch our modular conveyor components. These building blocks enable and simplify customization: simplicity, flexibility, and efficiency are key. This is how we help system integrators build new systems faster and easier, or expand existing installations. With ConveyorBricks, it's a breeze!

Bendur ConveyorBricks is the ideal solution for system integrators looking for greater speed, flexibility, and simplicity.

Save time, both in production and on-site

You'll not only save time through simple production and fast delivery, but also through improvements that significantly reduce the required on-site time compared to existing systems.

No more hassle with designing and manufacturing individual brackets and parts. Our complete system offers everything you need and is easy to install with just one impact wrench (13).

For example: Our well-designed system saves you unnecessary time on measuring and marking. The support is exactly the same width as the conveyor belt, making it easy to determine where the system can be installed, for example, using a smudge or impact line.

Limitless flexibility, Premium quality

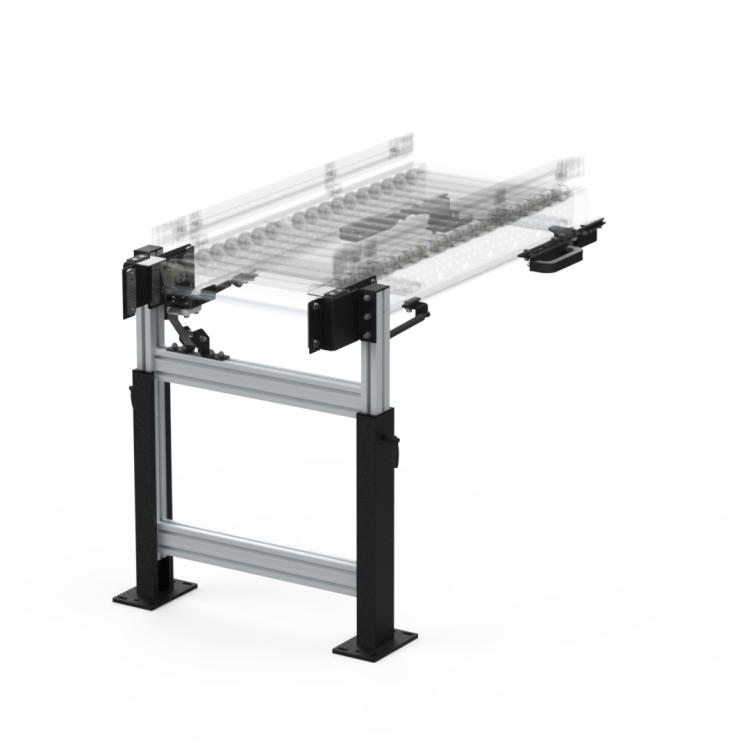

The modular Bendur ConveyorBricks system ensures that customization truly means customization. The individual components are designed to be used for a wide range of applications.

This way, designing a conveyor system evolves into a truly unlimited project, making not only new systems easier, cheaper, and faster to implement, but also existing systems easily expandable. Whether it's a belt conveyor, roller conveyor, or mat conveyor.

All of this without compromising on quality; all the hardware we manufacture meets the highest quality and sustainability standards.

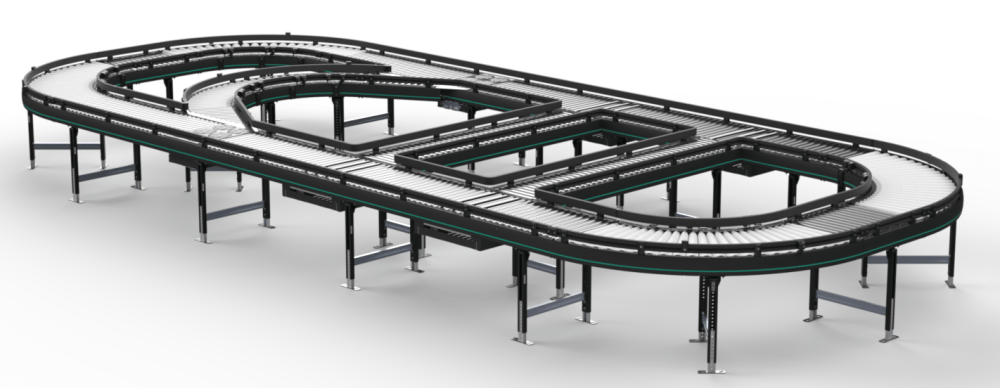

Chosen by PostNL

A prime example of the power of ConveyorBricks is its deployment at PostNL's fulfillment center in Houten, where more than 11,000 orders are processed daily. We provided the hardware for the transport system that transports goods from the Autostore to the packaging line and ultimately to the trucks. Thanks to its modular design, fast delivery, and easy installation, the system was operational within a few weeks—fully integrated into an existing, busy environment. This confirms that even the biggest companies opt for speed, flexibility, and reliability.

Well designed: a system that is finished

It's the little things that truly make the big picture something great. We'd like to share a few examples of the small and large improvements we've made to ConeyorBricks components.

Profiles: Flexibility and Customization

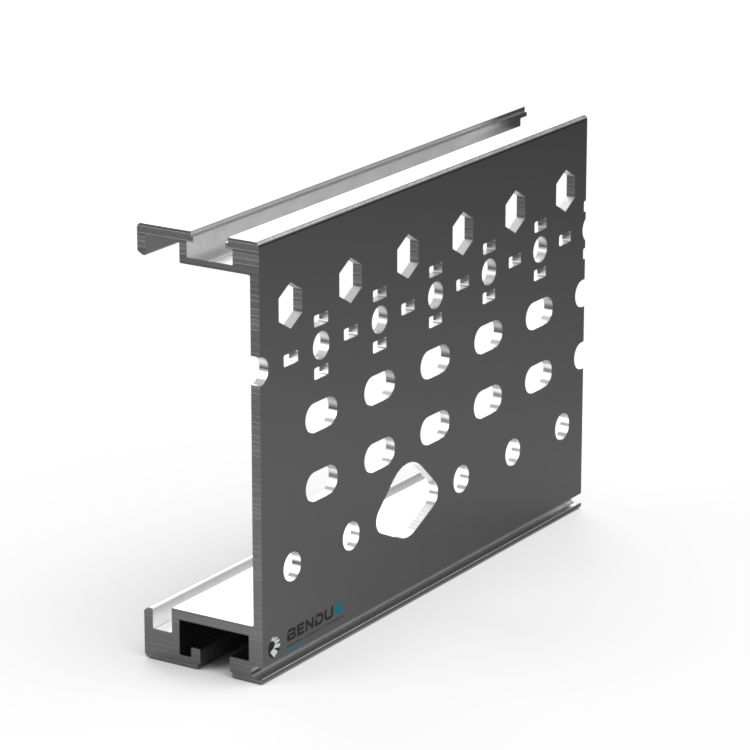

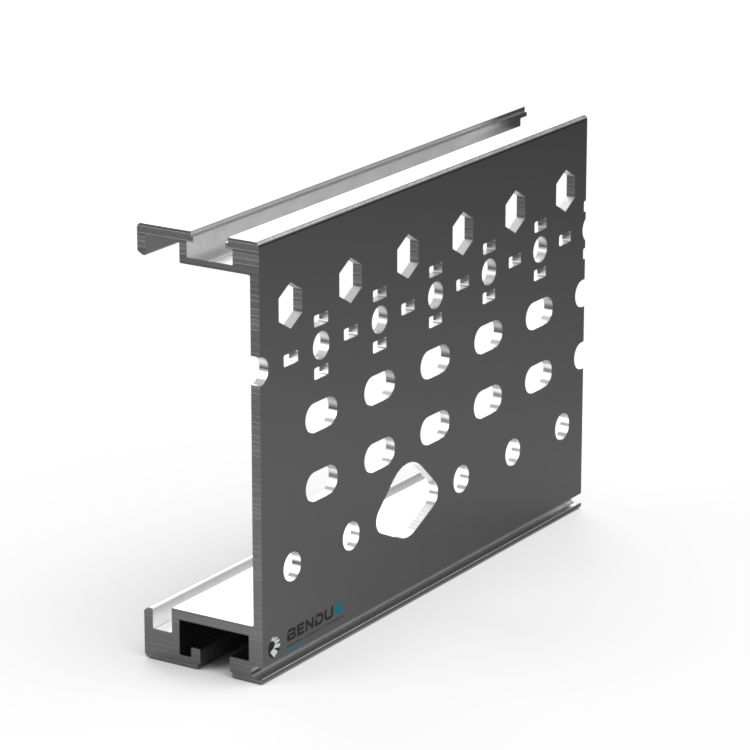

1. Side profiles with hole pattern

Our profile with a hole pattern is specially designed for versatile and quick installation. The hole pattern, with a 30 mm spacing, is suitable for virtually any conceivable transport system and offers advantages for:

- Placing rollers for a roller conveyor.

- Mounting slide plates or strips for belt conveyors and mat conveyors.

- Installing cabling, tie-wraps, or connecting systems.

Thanks to the well-thought-out design, additional parts and adjustments can be easily added afterwards without additional mechanical processing.

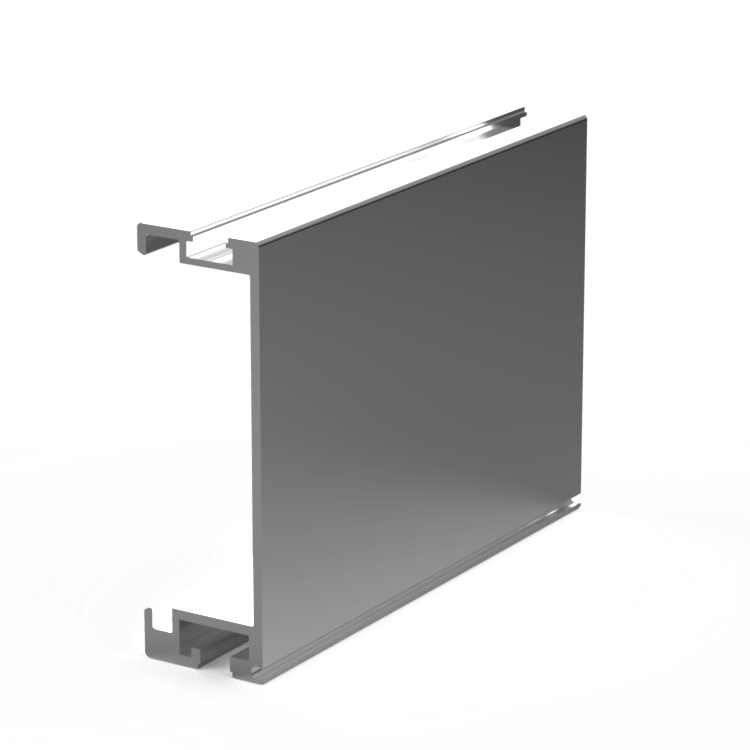

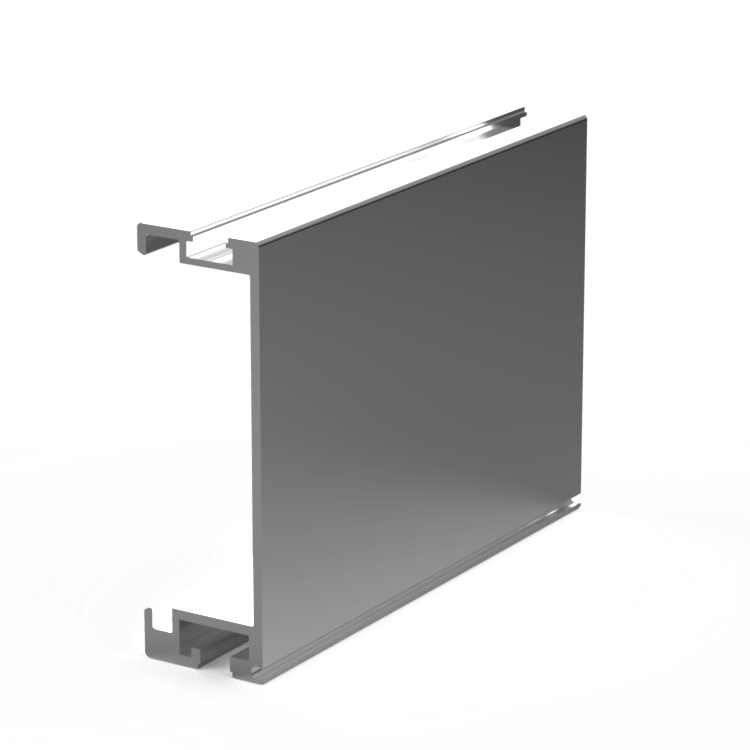

2. Side profiles without hole pattern

The profile without a hole pattern offers maximum freedom for system integrators. This profile is ideal for specific requirements, such as positioning holes for mounting rollers or openings for installing sensors or reflectors.

In addition, we can roll this profile, allowing us to easily create curves. This flexibility allows us to create complex designs that perfectly match the unique requirements of a project.

With these customization options, ConveyorBricks offers solutions that are both versatile and innovative, tailored to unique applications and specific customer needs.

3. Side guide: Robust and efficient

Onze zijgeleiding is ontworpen met dezelfde filosofie van flexibiliteit en efficiëntie:

- Robustness: The design can withstand heavy-duty applications, such as transporting heavy crates, and provides stability for sensors and reflectors, minimizing error detection.

- Minimal friction: The unique shape of our aluminum side guide profile reduces friction between the product and the side guide, making transport systems more efficient and sustainable.

- Seamless transport direction: The design prevents goods from getting caught on side guide components, which ensures smooth transit.

4. And more:

- Sensors that can look upwards, not straight up, to detect damaged, bent, or bulging boxes.

- The support is easily and infinitely adjustable, eliminating the need to fiddle with adjusting feet.

- The entire system can be installed with a single 13 mm impact wrench.

- No interruptions in the side guides, so nothing gets stuck.

Suitable for belt conveyors, roller conveyor systems, and mat conveyors.

Bendur conveyor components are available for:

-

System integrators seeking reliable solutions that not only improve efficiency but also save time and money through easy-to-implement systems. Thanks to modular and easily adaptable components, projects can be completed faster and more flexibly.

-

Machine builders looking for flexible components for their projects. With our system, you can quickly assemble a specific transport system, saving time and resources that can be better spent.

-

E-commerce companies that want to benefit from efficient and reliable logistics solutions. Bendur components offer the flexibility to effortlessly set up warehouses and distribution centers and adapt them to changing needs. Whether it's seasonal peaks or long-term growth, our system ensures that your business operations run smoothly, smoothly, and efficiently, with the assurance that your systems are easily expandable.

-

Homeowners: The Willy Wortel who places his crosscut saw between two roller conveyors at home for easy loading and unloading of materials, or who wants to equip his camper or van with a roof rack.

Want to know more? Contact us.